Company

Mission Statement

MHD aim to assist customers reducing their environmental footprint, while increasing product quality and production efficiency by designing, manufacturing and implementing new, high-end technologies and solutions.

- Reaching their sustainability goals,

- Increasing their production efficiency,

- Increase product quality.

History

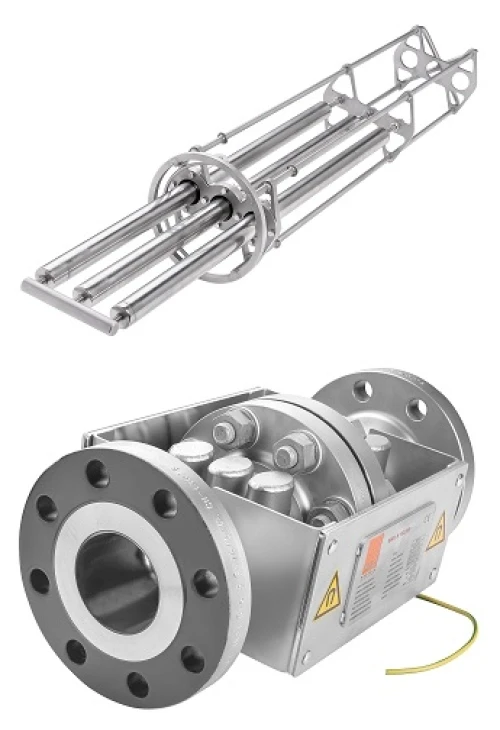

Designed the DESCALER magnetic module.

Designed the FLOWMAG magnetic module.

From here on continuous improvement on the PACMAN based on experience and customer feedback.

First PACMAN-150 delivered to Ford Genk, Belgium.

Patent application filed for PACMAN.

Move to engineering and stainless steel production facility of main contractor Ozephius in Oud-Beijerland, NL.

Patent application filed for PREMAG.

Introduced modular design with optional features.

100 PACMAN-150 separators delivered!

PREMAG patent granted!

100 FLOWMAG modules delivered!

Designed and delivered the first FLOWMAG Plus for in high pressure applications and/or aggressive fluids.

Distributors

Beijing Hydrotech Filtration Technology Co., Ltd. (Headquarters)

C 12 Tech. Road, Economic Development Zone, Mi-Yun, Bejing 101500

Beijing Hydrotech Filtration Technology Co., Ltd. (Beijing Office)

1202 Suite Everlast Plaza, No. 39 Anding Road, Chaoyang District, Beijing 100029

T +86 10 8280 9901 / 02 /03 / 04

E hydmem@hydrotech.cn

W www.hydrotech.cn

Unique Products and Services

22 Milner Street, Port Elizabeth, 6070

T +27 41 367 4336

E eugene@uniqueps.co.za

W www.uniqueps.co.za

Alting Rus LLC

142701, Vidnoe, Moscow region, Prospect Leninskogo Komsomola, 41, of. 209

T +7 495 107 5203

E yg@altingrus.ru

W www.tmir.ru

JMXworks

Plot Number 5/13, HUDA Industrial Area, Dharuhera, Rewari, Haryana, 22106

T +91-1274-242232

E sandeep@jmxworks.com

W www.jmxworks.com

51 Covington Street, Hamilton, ON L8E 2Y4, Canada

T +1 289-362-6108

E sales@kfactorfilter.com

W www.kfactorfilter.com